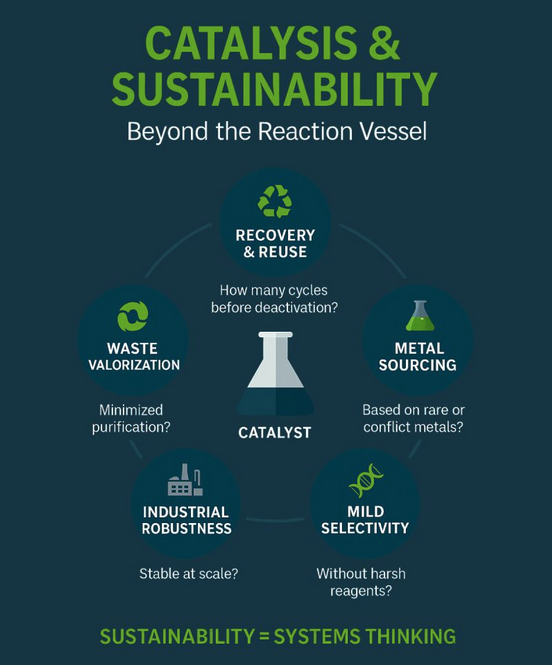

When we talk about “green catalysis,” the conversation often stops at milder conditions or improved yields. But the true environmental impact of catalysis goes far beyond the reaction vessel.

A catalyst may enable lower temperatures or faster conversions, but that’s only the beginning. To truly assess its sustainability, we must adopt a systems-level perspective:

🔁 Catalyst Recovery & Reuse: How many cycles can it survive before deactivation? What purification is needed before reuse?

🧪 Metal Sourcing & Scarcity: Is the catalytic center based on rare or conflict metals? What are the geopolitical or ecological costs of sourcing them?

♻️ Waste Valorization: Can we integrate the catalyst in a process that minimizes post-reaction purification or byproduct generation?

🧬 Selectivity Under Mild Conditions: Can the catalyst maintain performance without excessive energy input or harsh reagents?

🏭 Industrial Robustness: Does it tolerate impurities, scale, and remain stable under production conditions?

Green chemistry isn’t just about minimizing environmental harm. It’s also about designing processes for long-term resilience. Catalysis is central to this effort, but only when we stop thinking of it as an isolated reagent and start viewing it as an actor in a complex ecosystem of sustainability.

At Alza & Associates, we believe the next leap in catalytic innovation won’t come from isolated breakthroughs. It will come from integrative thinking across chemistry, engineering, sourcing, and waste management.